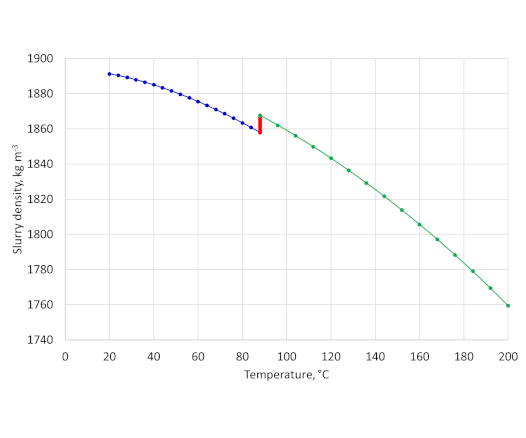

API sedimentation tests

June 8, 2020

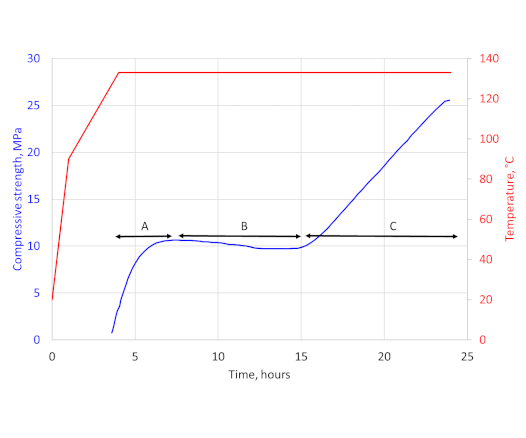

Compressive strength development at high temperature

December 10, 2020

Errors in rheological measurements

Maximum recommended rotation speed

Ramp up and ramp down measurements

|

|

Reading |

|||

|

Rotational Speed (rpm) |

Ramp-up |

Ramp-down |

Ratio |

Average |

|

3 |

8 |

5 |

1.6 |

6.5 |

|

6 |

9 |

7 |

1.29 |

8 |

|

30 |

18 |

16 |

1.13 |

17 |

|

60 |

27 |

26 |

1.04 |

26.5 |

|

100 |

39 |

39 |

1 |

39 |

|

200 |

69 |

70 |

0.99 |

69.5 |

|

300 |

97 |

- |

- |

97 |

|

Rheometer configuration |

R1-B1-F1 |

|||

|

Conditioning |

Atmospheric pressure, 30 minutes at 50°C |

|||

|

Initial slurry temperature |

50°C |

|||

|

Final slurry temperature |

48°C |

|||

Model fitting - Bingham Model

Even though curve fitting is easy to do with spreadsheets there is still a tendency for people to use just two data points to fit the data, which was the case with the peer reviewed journal article (using 600 and 300 rpm data points). API RP 10B-2 clearly states that 2-point calculations should not be used.

As an example, I will use the average data points from the above table - I have converted the rpm and dial reading to shear rate (s-1) and shear stress (Pa) for the following analysis. Data fitting for the Bingham model has been done using the built in linear regression function in Excel.

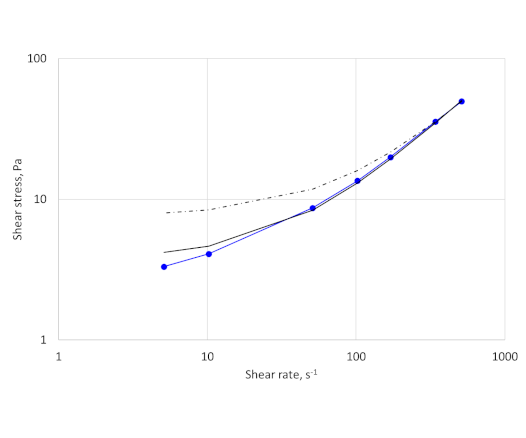

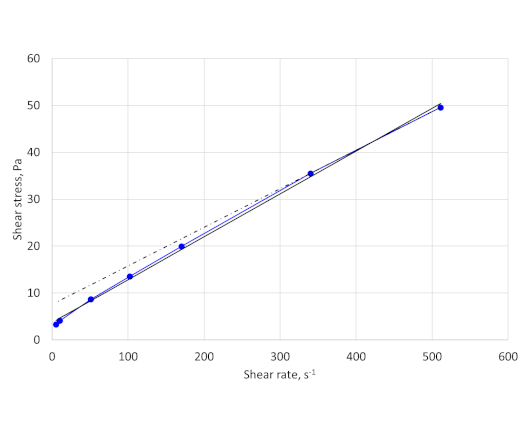

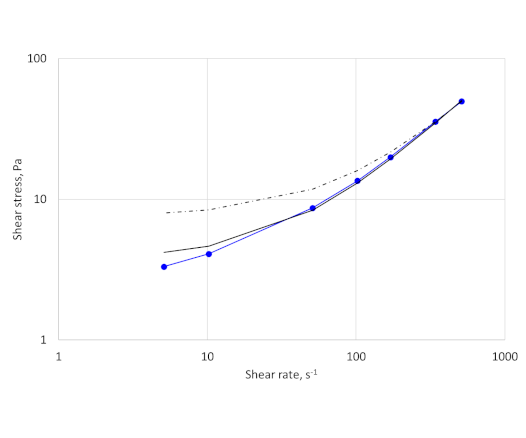

The results for the fit are shown in Figure 1.

The curve fit using just the two data points at the highest shear rates does not match the data over the entire range and gives a yield stress value of 7.6 Pa. The curve fit using all the data points give a much better fit of the data over the entire range. The yield stress value is 3.7 Pa. The reading at 5.1 s-1 (3 rpm) is 3.3 Pa.

In most cases fitting the data using all the data points will give a higher plastic viscosity and lower yield stress than using a two-point data fit at high shear rates. Exceptions will be fluids exhibiting dilatancy (shear thickening).

The differences between the fits and the actual data can be seen more clearly on a log-log (Figure 2). The fit using all 7 data points overestimates the low shear rate viscosity but is much closer to the data than the two-point fit.

Plotting the data on a log-log plot also shows that there are no signs of slippage at the wall, as the data points follow a smooth curve.

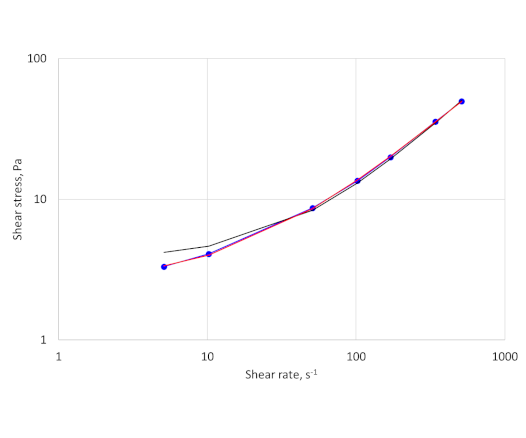

Model fitting – Herschel-Bulkley model

The Herschel-Bulkley model is a three-parameter model that combines power law and Bingham plastic behaviour.

τ = τy + kγ̇n

Where k is the consistency index, and n is the power law index.

The Herschel-Bulkley model simplifies to the Bingham model (if n=1) and to the power law model with τy=0.

Microsoft Excel can also be used to fit the Herschel-Bulkley model to a set of data as follows:

- Convert the rpm values and average dial readings to shear rate (s-1) and shear stress (Pa) respectively.

- Estimate a yield stress value, this can be from 0 to the shear stress determined at 3 rpm (5.1 s-1).

- Use this estimated yield stress to perform a linear regression on log((shear stress – estimated yield stress)/Pa) v log(shear rate/s-1) to give n and k.

- Calculate the sum of the squares of the differences between the data points and the calculated values.

- The Excel solver function can then be used to determine the value of the yield stress, and the associated n and k values, that minimises the sum of the squares.

The best fit to the data above has:

τy=2.6 Pa, n=0.897, k=0.175 Pa.sn

The fit is plotted in Figure 3:

There is a more detailed discussion of fitting rheological models to data of drilling and cementing fluids in:

Hans Joakim Skadsem and Arild Saasen, “Concentric cylinder viscometer flows of Herschel-Bulkley fluids”, Appl. Rheol. 2019; 29 (1):173–181.

This is an open access paper available at: https://doi.org/10.1515/arh-2019-0001