Geopolymer Patent Publications

September 17, 2019

API sedimentation tests

June 8, 2020Introduction

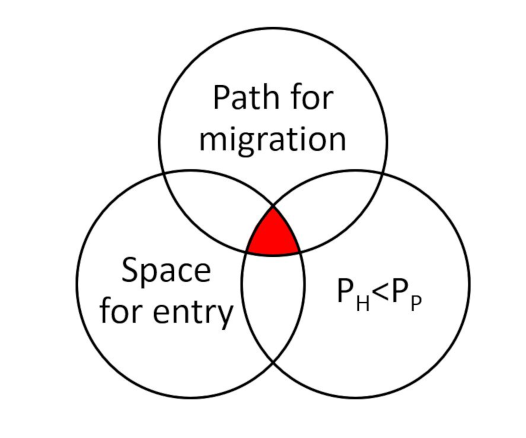

For annular gas migration to occur (red zone) three conditions must be met as shown in the diagram above.

- The hydrostatic pressure (PH) in the annulus decreases to a value ≤ the pore pressure (PP) of the gas bearing zone

- There must be space in the annulus to allow gas to enter

- There is a path present through which the gas can migrate

Gas migration can occur during cement placement (immediate gas migration), between the end of the cementing operation and setting of the cement (short-term gas migration) and after the cement has set (long-term gas migration). Latex additives are used to prevent short-term gas migration.

Latex additives

The use of latex additives, and in particular styrene-butadiene latices, for gas migration control was first revealed in US4,537,918 granted in 1985 (with a priority date of April 1982). A key component for the successful application of the latex to control gas migration was, and is, the selection of the stabiliser package.

The first paper describing field applications of a latex additive was SPE 17629. This paper emphasises the importance of good fluid displacement and the optimum design of a well dispersed, non-gelling, cement slurry with a short transition time from the liquid to the set state. The latex additive provides excellent fluid loss control and reduces the permeability of the cement to gas.

Fluid loss from the cement slurry can adversely affect all three root causes of gas migration. For example, loss of fluid can lead to increased slurry gelation and a consequent drop in annular pressure and loss of filtrate volume can provide space for gas entry. Also, poor fluid loss control may lead to higher permeability filtercakes which will influence the gas migration path. A detailed discussion can be found in Well Cementing, 2nd Edition, Erik Nelson and Dominique Guillot, Schlumberger: Sugar Land, TX, USA, 2006; ISBN 0978853008.

Most of the latex additives that are available today for gas migration control are based on styrene-butadiene latices. The sizes of the latex particles are from around 150 nm to 250nm and the solids content of the latices are from 40 to 50% by weight. Patent US4,537,918 described suitable ratios of styrene:butadiene ranging from 70:30 weight percent to 30:70 weight percent. There is little publicly available information on the styrene:butadiene ratios of commercial products, but what is available indicates a wide range of styrene-butadiene ratios is used.

Suppliers of latex-based gas migration control additives

Below is a table of companies (in alphabetical order) that have latex-based gas migration control additives in their product portfolios. The list is limited to companies that have a minimum of details (product name and indication that it is a latex-based additive for gas migration control) of the products on their websites.

There are some major companies missing from the list. This does not indicate that these companies do not have latex-based additives but that I have not found information on their websites.

| Additives | Temperature limit | Comments | |

| Aubin Group | up to 160°C [320°F] | ||

| up to 160°C [320°F] | |||

| CFL-387 | up to 160°C [320°F] | ||

| BASF | Basoblock ND 614 | Styrene-butadiene latex | |

| Dosas | GASSTOP™ 3000 | 120°C to 200°C [212°F to 392°F] | Styrene-butadiene latex |

| Drilling Specialties Company | DIACEL® LX200 Cement Fluid Loss Additive | up to 93°C [200°F] | Indicated as gas migration control on the cementing product page |

| Elkem | Microlatex™ | Styrene-butadiene latex | |

| EOC Group | Exodrill 5040 | 70°C to 170°C [158°F to 338°F] | Modified styrene-butadiene latex |

| Exodrill 5000 | up to 204°C [400°F] | Sulphonated styrene-butadiene latex | |

| Halliburton | Latex 2000™ Cement Additive | up to 193°C [380°F] | |

| Latex 3000™ Cement Additive | up to 204°C [400°F] | High salt content slurries | |

| i4CS | SimaWELL® GBK-001 L | up to 204°C [400°F] | |

| ISI Oilfield Chemicals | ILX-2000 PLUS | up to 149°C [300°F] | Styrene polymer latex |

| Mallard Creek Polymers | Tylac® 4901 | Styrene-butadiene latex (non-carboxylated) | |

| NRG | NRG-LXL 150 | up to 149°C [300°F] | Styrene-butadiene latex (carboxylated) |

| Riteks | Riteks GCL-4 | up to 177°C [350°F] | High salt content slurries |

| SLB | D600G GASBLOK* | 66°C to 149°C [150°F to 300°F] | * GASBLOK is a mark of Schlumberger |

| D620 GASBLOK | 66°C to 149°C [150°F to 300°F] | ||

| D700 HT GASBLOK | 121°C to 177°C [250°F to 350°F] | ||

| SYENSQO | Rhodibloc® GC | up to 149°C [300°F] | Styrene-butadiene latex |

|

Synthomer |

Verilok 343 | up to 100°C [212°F] | Styrene-butadiene latex |

| Verilok 362 | up to 121°C [250°F | Styrene-butadiene latex | |

| Verilok 443 | up to 177°C [350°F] | Styrene-butadiene latex | |

| Verilok 552 | up to 204°C [400°F] | High salt content slurries | |

| Trinseo | LIGOS™ Y300 | Styrene-butadiene latex | |

| Zoranoc | ZOC-GR5 | up to 149°C [300°F] |

The web links were re-checked December 4th 2024. A few links were no longer available and have been removed. However, the temperature limits, latex type and salt compatibility information from the company websites as of April 2020 have been kept. Company name changes have also been made.

If you wish to add other suppliers to this list please use the contact form, providing the details, including web link.