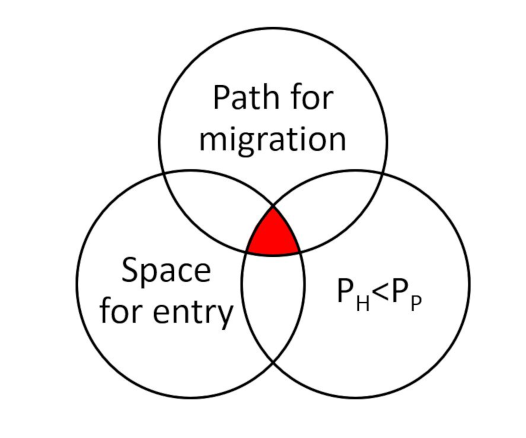

Latex additives for gas migration control

January 10, 2020Rheological measurements

July 3, 2020Have you wondered why the density of the set cement may be lower than designed in high temperature sedimentation tests?

Have you ever noticed that slurry has escaped from the top of the sedimentation tube during testing?

Introduction

The API sedimentation test (API RP 10B-2, Second Edition, April 2013, section 12.5) is an important test used to evaluate the stability of a cement slurry in static conditions, i.e. once placed in the well. The laboratory test method consists of placing the cement slurry in a metal tube and exposing the slurry to appropriate temperature and pressure conditions until set. The slurry cylinder is then cut into segments and the density of each segment is determined. Differences in the density of the segments may indicate instability and the need to redesign the cement slurry. Please refer to the API procedure.

Depending on test conditions the segment slurry density may be lower than expected and/or overflowing of the slurry from the test cell may be observed. These observations can be explained by the thermal expansion of the aqueous phase of the cement slurry. The phenomenon is discussed below, using an idealised example; ignoring the minor contribution from the thermal expansion of the solids and other slurry additives.

Data for the thermal expansion and compressibility properties of water used in these examples are taken from the NIST website, using Fluid Properties under “Other data available”.

Slurry density changes

A cement slurry formulated with class G cement, 35% silica by weight of cement and water at a density of 1890 kg m-3 [15.8 lbm/gal]. This slurry contains 55% by volume of water and 45% by volume of solids.

The slurry is formulated and mixed at 20°C and then conditioned. For high temperature tests the conditioned slurry is placed in a sedimentation tube pre-heated to 88°C and placed in a pre-heated curing chamber. At these conditions, the water has expanded, and the density of the slurry has decreased.

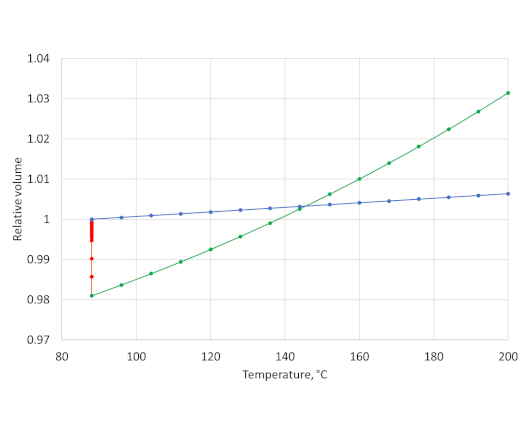

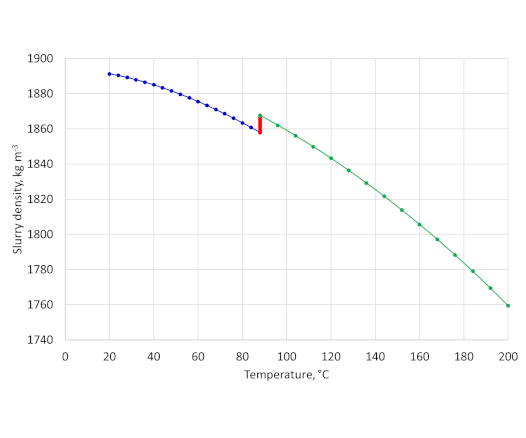

The change in slurry density due to the expansion of the aqueous phase under atmospheric pressure while heating to 88°C is shown by the blue line in Figure 1.

Typical laboratory curing conditions

Now the sedimentation tube (heated to 88°C) is placed in a pressurised curing chamber and the pressure increased; 20.7 MPa (3000 psi), a typical laboratory value is used in this example. The API procedure recommends a minimum 3.45 MPa (500 psi), although this may need to be increased for curing temperatures above about 200°C (392°F) to prevent boiling.

The increased pressure (at constant temperature of 88 °C) compresses the slurry so the density increases (red line in Figure 1). In this ideal example, there is no entrained air in the slurry – puddling has been perfect!

As the temperature is increased further the water expands and the slurry density decreases (green line). Under these conditions the initial slurry with a density of 1890 kg m-3 (15.8 lbm/gal) has a density of 1760 kg m-3 (14.7 lbm/gal) at a temperature of 200°C and pressure of 20.7 MPa.

More realistic temperature and pressure curing conditions

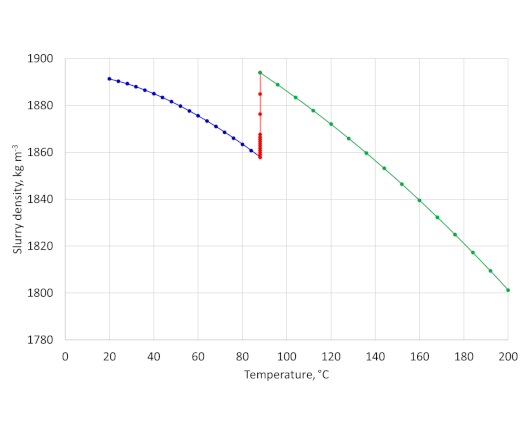

If the test pressure is increased to 82.8 MPa (12000 psi), more typical for high temperature applications, then the slurry density at 200°C is 1800 kg m-3 (15.0 lbm/gal) as shown in Figure 2. The red line corresponds to the increase in density as pressure is applied up to 82.8 MPa at a constant temperature of 88°C.

Comments

The most important point to make is that, even though the density of the set cement may be lower than that measured for the starting slurry, the test method will still indicate whether the slurry is stable (no variation in density between segments) or unstable (significant variation in density between segments). As discussed in the API document (section 12.5.2.19) what is acceptable varies with the application.

This analysis has not considered the effect of chemical shrinkage. The amount of chemical shrinkage will depend on the degree of cement hydration and the phases formed (CSH at lower temperatures and possibly tobermorite and xonotlite at higher temperatures, depending in the curing time). The effect of chemical shrinkage will be to increase the density of the set cement, perhaps by a few tens of kg m-3 (a few tenths of lbm/gal).

Overflowing sedimentation tubes

To determine whether cement slurry will overflow from the sedimentation tube during heating the change in volume of the sedimentation tube with temperature needs to be considered. For the examples below brass tubes have been “used”. Brass has a linear thermal expansion coefficient of 19 x 10-6 °C-1.

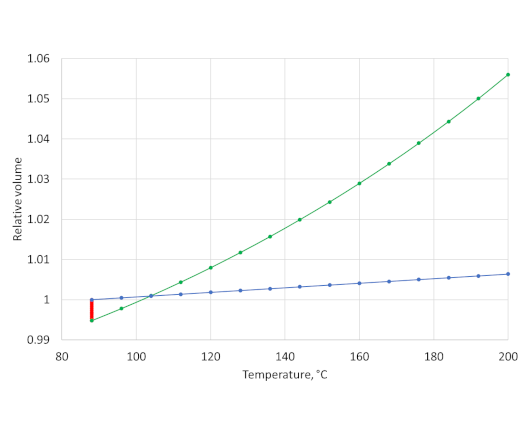

At 88°C and atmospheric pressure the tube is filled with slurry so the relative volumes of slurry and cell are set to 1 (Figure 3). As pressure is applied at 88°C the slurry volume decreases due to the compressibility of the aqueous phase, but the internal volume of the brass cell remains effectively constant (brass has a very high bulk modulus).

Then as the temperature is increased the internal volume of the cell increases (blue line in the figure above) and the volume of the slurry increases at a higher rate (green line in Figure 3). At a temperature of around 105°C the volume of the slurry is now the same as the internal volume of the cell. As the temperature increases further slurry will start to escape from the top of the cell.

A typical sedimentation tube (2.54 cm diameter, 20 cm long) has a volume of 101 cm3 so at 3.45 MPa (500 psi) and 200°C approximately 5 cm3 of slurry will escape from the tube.

If a higher pressure is used (Figure 4), then the slurry compresses further and slurry will not flow from the tube until a temperature of approximately 145°C is reached. At 200°C approximately 2 cm3 of slurry will escape from the tube.